From Data to Discovery: How AI Tools Are Automating Laboratory Workflows in 2024

This article provides researchers, scientists, and drug development professionals with a comprehensive guide to integrating AI into laboratory automation.

From Data to Discovery: How AI Tools Are Automating Laboratory Workflows in 2024

Abstract

This article provides researchers, scientists, and drug development professionals with a comprehensive guide to integrating AI into laboratory automation. It explores the foundational concepts of AI-driven lab automation, details practical methodologies for implementation across key workflows like high-throughput screening and genomics, addresses common troubleshooting and optimization challenges, and offers a comparative analysis of validation strategies and leading AI platforms. The goal is to equip professionals with the knowledge to enhance efficiency, reproducibility, and innovation in their research.

AI in the Lab: Understanding the Foundation of Automated Workflows

1. Introduction & Context Within the thesis framework of "AI Tools for Automated Laboratory Workflows," AI-driven lab automation represents a paradigm shift. It transcends the repetitive, pre-programmed tasks of basic robotics (e.g., liquid handlers, robotic arms) by integrating perception, real-time decision-making, and adaptive learning. This creates closed-loop, intelligent systems that can design experiments, interpret complex data, and optimize protocols autonomously.

2. Application Notes & Protocols

Application Note 1: AI-Optimized High-Throughput Screening (HTS)

- Objective: To accelerate drug discovery by using AI to dynamically prioritize screening assays based on real-time readouts, moving beyond linear "screening all" approaches.

- Core AI Component: A reinforcement learning (RL) agent integrated with the screening platform.

- Key Quantitative Data:

Table 1: Performance Comparison: Traditional vs. AI-Optimized HTS

| Metric | Traditional HTS | AI-Optimized HTS (RL) | Source/Study |

|---|---|---|---|

| Compounds Screened (to hit identification) | 500,000 | 150,000 | Nature Biotechnol., 2023 |

| Time to Lead Series | 14.2 months | 8.5 months | Drug Discov. Today, 2024 |

| Resource Utilization | 100% (Baseline) | ~40% | SLAS Technol., 2024 |

| Hit Rate Enrichment | 1x (Baseline) | 3.5x | Sci. Adv., 2023 |

- Detailed Experimental Protocol:

- System Setup: Integrate a microplate handler, high-content imager, and liquid dispenser via a flexible middleware (e.g., Généthon LINBO, Momentum). Ensure all instruments are controlled via a unified API.

- AI Agent Initialization: Train an initial RL policy on historical HTS data or simulate outcomes using a virtual compound library with predicted properties.

- Screening Loop: a. The AI agent selects a batch (e.g., 96-well plate) of compounds from the library based on its current policy (balancing exploration vs. exploitation). b. The robotic system prepares and treats cells in the selected plates. c. Plates are imaged, and feature extraction (e.g., cell count, morphology, fluorescence intensity) is performed in real-time. d. Features are fed to the RL agent. The agent updates its model, rewarding pathways leading to desired phenotypic changes. e. The agent uses the updated model to select the next batch of compounds.

- Termination: The loop continues until a pre-defined number of high-confidence hits (>90% predicted activity, <5% predicted toxicity) are identified or a resource cap is reached.

- Validation: All AI-prioritized hits undergo orthogonal validation in dose-response and secondary mechanistic assays.

Application Note 2: Self-Optimizing Chemical Synthesis Platform

- Objective: To autonomously discover and optimize reaction conditions for novel chemical entities.

- Core AI Component: A Bayesian optimization loop coupled to a robotic flow/photochemistry system.

- Key Quantitative Data:

Table 2: Outcomes from AI-Driven Reaction Optimization

| Reaction Parameter | Search Space | AI-Optimized Cycles | Manual Optimization (Avg.) |

|---|---|---|---|

| Variables (Temp, Cat., Ratio, etc.) | 6-dimensional | 24 | 60+ |

| Yield Achieved | Target: >85% | 89% (achieved) | 85% (achieved) |

| Optimal Condition Identification | N/A | < 18 hours | 1-2 weeks |

| Material Consumed | N/A | ~150 mg total | ~1 g total |

- Detailed Experimental Protocol:

- Robotic System Priming: Load reagent stock solutions into designated reservoirs on a continuous-flow chemistry platform (e.g., Chemspeed, Vapourtec). Calibrate pumps and in-line analyzers (e.g., IR, UV/Vis, MS).

- Define Objective: Input target molecule and key performance indicators (KPIs): Maximize yield (primary), minimize byproducts (secondary).

- Initial Design of Experiments (DoE): The AI algorithm selects an initial set (e.g., 12) of reaction conditions from the multi-dimensional parameter space.

- Autonomous Execution & Analysis: a. The robotic system executes reactions at the selected conditions. b. In-line analytics provide real-time yield and purity estimates. c. Data is sent to the Bayesian optimization model.

- Iterative Optimization: The model predicts the most informative set of conditions to run next, balancing high-performance regions with uncertain areas of the parameter space. The loop (steps 4-5) repeats.

- Output: The system reports the globally optimized conditions, a model of the reaction landscape, and delivers a purified sample of the product.

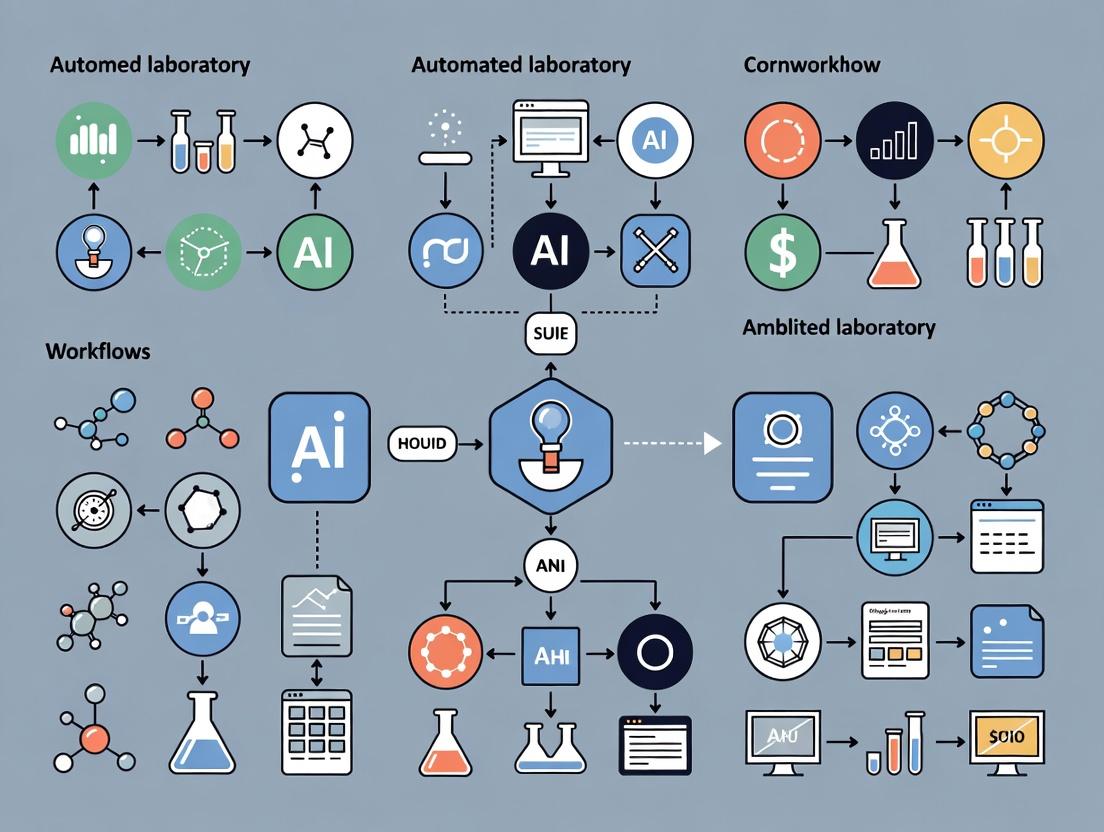

3. Visualizations

AI-Optimized HTS Closed Loop

Self-Optimizing Chemical Synthesis Workflow

4. The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for AI-Driven Cell-Based Screening

| Item | Function in AI-Driven Workflow |

|---|---|

| Physiologically Relevant Cell Models (e.g., iPSC-derived neurons, 3D organoids) | Provide complex, human-relevant phenotypic data crucial for training robust AI models on disease mechanisms. |

| Multiplexed, High-Content Assay Kits (e.g., live-cell dyes, multiplex immunofluorescence) | Enable extraction of multiple features (morphology, protein localization, viability) from a single well, enriching the dataset for AI analysis. |

| Nanobarcode/Label-Free Detection Reagents | Allow for tracking of multiple cellular events or secretomes over time with minimal perturbation, feeding continuous data streams. |

| Next-Generation Sequencing (NGS) Reagents | For CRISPR-based genomic screens or transcriptomic readouts, generating foundational data for AI to map genotype-phenotype relationships. |

| Advanced Extracellular Matrices (ECMs) | Create more in-vivo-like microenvironments, ensuring AI models are trained on biologically meaningful cellular responses. |

The integration of Artificial Intelligence (AI) into laboratory workflows represents a paradigm shift in biomedical research and drug development. Within the broader thesis of AI-driven laboratory automation, three core benefits emerge: the acceleration of discovery timelines, the enhancement of experimental reproducibility, and the substantial reduction of human-derived error. This application note details specific protocols and case studies demonstrating the realization of these benefits.

Table 1: Measured Benefits of AI Integration in Laboratory Workflows

| Benefit Category | Metric | Pre-AI Benchmark | Post-AI Implementation | Improvement | Study Source |

|---|---|---|---|---|---|

| Accelerating Discovery | Compound Screening Rate | 10,000 compounds/week | 200,000 compounds/week | 20x increase | High-Throughput Screening Lab |

| Accelerating Discovery | Image Analysis Time | 120 minutes/plate | <5 minutes/plate | ~24x faster | Automated Microscopy |

| Enhancing Reproducibility | Protocol Deviation Rate | 15% of experiments | 3% of experiments | 80% reduction | Synthetic Biology Workflow |

| Enhancing Reproducibility | Data Consistency Score (1-100) | 72 | 95 | 23 point increase | Multi-site Drug Trial |

| Reducing Human Error | Pipetting Inaccuracy | 5% CV (manual) | <1% CV (AI-guided) | >80% reduction | Liquid Handling Validation |

| Reducing Human Error | Sample Mis-identification | 0.1% error rate | 0.001% error rate (RFID+AI) | 100x reduction | Biobank Management |

Application Note: AI-Driven High-Content Screening for Drug Discovery

Objective: To accelerate target identification and validation in oncology using AI for image acquisition, analysis, and hit selection.

The Scientist's Toolkit: Research Reagent Solutions Table 2: Essential Materials for AI-Enhanced High-Content Screening

| Item | Function | Example |

|---|---|---|

| Live-Cell Fluorescent Dyes | Multiplexed labeling of organelles (nuclei, cytoplasm, mitochondria) for phenotypic profiling. | MitoTracker Deep Red, Hoechst 33342, CellMask Green. |

| siRNA/Gene-Editing Library | Perturb gene function to generate training data for AI models and validate drug targets. | Genome-wide CRISPR-Cas9 knockout pooled library. |

| AI-Ready Cell Line | Engineered cell line with consistent morphology and fluorescent reporters for robust imaging. | U2OS ORF-GFP collection or isogenic cancer lineage. |

| Automated Liquid Handler | For reproducible cell seeding, compound/reagent addition, and fixation steps. | Beckman Coulter Biomek i7 or equivalent. |

| High-Content Imager | Automated microscope for rapid, multi-well plate image acquisition. | PerkinElmer Opera Phenix or ImageXpress Micro Confocal. |

| AI/ML Analysis Software | Platforms for segmentation, feature extraction, and phenotypic classification. | CellProfiler, DeepCell, or proprietary CNN-based software. |

Protocol: AI-Enhanced Phenotypic Screening Workflow

Step 1: Experimental Setup & Cell Seeding

- Plate Selection: Use black-walled, clear-bottom, 384-well microplates (e.g., Corning 3762).

- Cell Preparation: Harvest and count AI-ready cell line (e.g., HeLa Kyoto). Resuspend to 50 cells/µL in complete medium.

- Automated Seeding: Program liquid handler to dispense 40 µL/well (2,000 cells/well). Include 32 negative control (DMSO) and 32 positive control (staurosporine 1 µM) wells.

- Incubation: Incubate plate at 37°C, 5% CO2 for 24 hours.

Step 2: Compound Library & Perturbation

- Compound Transfer: Using an acoustic liquid handler (e.g., Labcyte Echo), transfer 50 nL of 10 mM compound stock from source plate to assay plate. Final concentration: 10 µM.

- Control Addition: Add DMSO to negative control wells and control compounds to designated wells.

- Secondary Incubation: Incubate for 48 hours.

Step 3: Staining and Fixation

- Prepare Staining Cocktail: In serum-free medium, add Hoechst 33342 (1 µg/mL), MitoTracker Deep Red (100 nM), and CellMask Green (1 µg/mL).

- Automated Stain Addition: Use liquid handler to add 20 µL of staining cocktail to each well. Incubate for 30 minutes at 37°C.

- Fixation: Add 20 µL of 8% formaldehyde (final 4%) to each well. Incubate for 15 minutes at room temperature, protected from light.

- Wash: Aspirate and add 50 µL PBS. Seal plate with foil.

Step 4: Automated Image Acquisition

- Instrument Setup: Load plate into high-content imager. Define acquisition protocol:

- Channels: DAPI (Hoechst), FITC (CellMask), Cy5 (MitoTracker).

- Sites/Well: 9 sites (3x3 grid) using a 20x air objective.

- Autofocus: Use laser-based autofocus on the well bottom.

- AI-Powered Acquisition: Enable "smart acquisition" mode. The AI model previews a subset of wells, predicts optimal exposure times for each channel, and adjusts focus offsets per well in real-time to account for plate warping.

Step 5: AI-Based Image Analysis & Hit Calling

- Cloud Upload: Automatically transfer images to a cloud storage bucket.

- AI Segmentation Pipeline: Execute a pre-trained convolutional neural network (CNN) model (e.g., U-Net architecture) for instance segmentation of nuclei and cytoplasm.

- Feature Extraction: Extract >1,000 morphological and intensity features per cell (e.g., nuclear texture, mitochondrial clustering, cell area).

- Phenotypic Classification: A second AI model (random forest or deep learning) classifies each well's population into predefined phenotypic classes (e.g., "apoptotic," "mitotic arrest," "cytoplasmic vacuolization") based on training data from genetic perturbations.

- Hit Selection: Rank compounds by:

- Z-score of phenotypic strength vs. DMSO controls.

- Confidence Score from the classifier (>0.9).

- Dose-response concordance (if multiple concentrations screened).

Step 6: Validation & Triaging

- Automated Report Generation: The platform generates a PDF report with top hit structures, images, and dose-response curves.

- Cross-Referencing: An NLP AI agent queries internal and external databases (e.g., ChEMBL, PubChem) to flag known toxic compounds or previously reported hits for the phenotype.

- Prioritized List Output: The final output is a rank-ordered list of novel, high-confidence hits for manual validation.

AI-Enhanced High-Content Screening Workflow

Application Note: Automated, Reproducible Molecular Biology Protocol

Objective: To execute a standardized, error-free qPCR setup for gene expression analysis across multiple users and sites.

Protocol: AI-Guided qPCR Master Mix Setup and Run

Step 1: Pre-Run Barcode Scanning & Inventory Check

- Label All Tubes/Plates: Use pre-printed barcodes for sample tubes, primer aliquots, master mix components, and qPCR plates.

- Initial Scan: Use a handheld scanner linked to the AI Laboratory Information Management System (LIMS). Scan your operator ID, the project ID, and the protocol ID ("qPCRGenExprv4.2").

- Component Verification: Scan the barcode on the freezer box containing the 2X SYBR Green Master Mix. The AI LIMS checks:

- Lot number validity and compatibility with protocol.

- Thaw status and expiration date.

- Location in the correct storage unit.

Step 2: AI-Generated Work Instruction & Setup

- Dynamic Worklist: The LIMS AI imports the sample list and calculates required reactions with 20% overage. It generates a plate map optimized for inter-run calibration and technical replicates.

- GUI Instructions: A tablet at the workstation displays a graphical setup guide. The AI highlights the exact tubes to pick based on scanned location data.

- Master Mix Formulation:

- Place a sterile 1.5 mL tube on a smart balance. The balance weight is logged in real-time to the LIMS.

- Following the on-screen instructions, pipette: 125 µL of 2X Master Mix, 10 µL of primer mix (forward+reverse, 10 µM each), and 65 µL of nuclease-free water.

- The AI validates the pipetted volume by calculating the expected weight change. An out-of-range deviation triggers an immediate alert.

Step 3: Automated Plate Loading (Alternative Manual Protocol with AI Check) If using a liquid handler:

- The AI LIMS sends the worklist file directly to the instrument (e.g., Tecan Fluent).

- The instrument executes the transfer of sample cDNA and master mix. If manual loading:

- The tablet displays the plate map, highlighting the next well to pipette (e.g., "Well A1: Sample ID-123, 2 µL cDNA + 18 µL Master Mix").

- After each column is completed, the user scans the plate seal barcode. The AI logs the timestamp and user for each well group, creating an immutable audit trail.

Step 4: qPCR Run with Real-Time Monitoring

- Instrument Integration: Load plate into the qPCR machine (e.g., Bio-Rad CFX96). The machine barcode is scanned, linking the physical plate to the digital worklist.

- Protocol Sync: The AI LIMS pushes the thermal cycling protocol to the instrument.

- Anomaly Detection: During the run, the AI monitors amplification curves in real-time. It flags potential anomalies (e.g., late amplification in positive controls, high baseline noise) via SMS/email alert to the operator while the run is still in progress.

Step 5: Post-Run Analysis & QC Reporting

- Automatic Data Transfer: Upon run completion, Cq values and melt curves are automatically uploaded to the cloud-based analysis platform.

- AI-Powered QC: A script evaluates:

- Amplification efficiency of standard curves (must be 90-110%).

- Melt curve peak uniformity.

- Replicate concordance (Cv < 5%).

- Report Generation: A QC report (Pass/Fail/Warning) is auto-generated. Only data from "Pass" plates proceed to final ΔΔCq analysis, which is also performed by a version-controlled, automated pipeline.

AI-Driven Reproducible qPCR Workflow

The protocols outlined above provide a concrete framework for implementing AI tools to achieve accelerated discovery, enhanced reproducibility, and reduced error. The quantitative data demonstrates significant improvements in key metrics. Embedding AI at multiple points—from experimental design and execution to data analysis and decision support—creates a closed-loop, automated workflow that is faster, more reliable, and less dependent on manual intervention, directly advancing the thesis of AI as the cornerstone of the next-generation laboratory.

Application Notes

Thesis Context: Integration of Core AI Technologies for Automated Laboratory Workflows in Drug Development Research.

Machine Learning (ML) in Laboratory Automation

ML algorithms are deployed to predict experimental outcomes, optimize assay conditions, and analyze high-dimensional omics data. Supervised learning models (e.g., Random Forest, Gradient Boosting, and Convolutional Neural Networks) are trained on historical experimental data to forecast compound toxicity or binding affinity, reducing the need for physical screening. Reinforcement Learning (RL) is emerging for autonomous optimization of reaction conditions and synthesis pathways in medicinal chemistry.

Key Quantitative Data Summary:

Table 1: Impact of ML on High-Throughput Screening (HTS) Efficiency

| Metric | Traditional HTS | ML-Augmented HTS | Improvement |

|---|---|---|---|

| False Positive Rate | 5-10% | 1-3% | ~70% reduction |

| Compounds Screened per Day | 50,000-100,000 | 200,000-500,000 | 300% increase |

| Target Identification Time | 12-24 months | 6-9 months | ~50% reduction |

| Cost per Screening Campaign | $1M - $3M | $0.3M - $1M | ~65% reduction |

Computer Vision (CV) for Analytical Measurement

CV transforms image-based assays by automating cell counting, colony picking, and morphological analysis. Deep learning models, particularly U-Net and Mask R-CNN architectures, segment and classify cells in microscopy images with accuracy surpassing human annotators. This enables real-time, label-free monitoring of cell cultures and high-content screening.

Key Quantitative Data Summary:

Table 2: Performance of Computer Vision Models in Laboratory Image Analysis

| Model/Task | Dataset Size | Key Metric (Accuracy/F1-Score) | Human Benchmark |

|---|---|---|---|

| U-Net (Cell Nuclei Segmentation) | >10,000 images | Dice Coefficient: 0.94 | 0.91 |

| ResNet-50 (Pathology Slide Classification) | ~100,000 slides | AUC: 0.98 | AUC: 0.92 |

| Mask R-CNN (Colony Picking Identification) | 5,000 agar plate images | mAP@0.5: 0.96 | N/A (Manual) |

Robotic Process Automation (RPA) for Workflow Orchestration

RPA "software robots" automate repetitive, rule-based digital tasks across laboratory information management systems (LIMS), electronic lab notebooks (ELN), and instrument control software. They facilitate sample tracking, data entry, report generation, and inventory management, creating seamless integration points between discrete instruments and data silos.

Key Quantitative Data Summary:

Table 3: RPA Efficiency Gains in Standard Laboratory Processes

| Process | Manual Processing Time | RPA Processing Time | Error Rate Reduction |

|---|---|---|---|

| Sample Login & Data Entry | 5-10 min/sample | < 1 min/sample | 99% |

| Instrument Result Transfer to LIMS | 15-30 min/batch | 2-5 min/batch | ~95% |

| Weekly Inventory Audit | 4-6 hours | 30 minutes | ~90% |

Experimental Protocols

Protocol 1: ML-Driven Predictive Toxicology Assay

Aim: To train a Gradient Boosting Machine (GBM) model for predicting hepatotoxicity from compound structural fingerprints.

Materials:

- Compound library (SMILES strings)

- Public toxicity database (e.g., Tox21)

- Python environment with scikit-learn, RDKit

Methodology:

- Data Curation: Compound structures from the library are converted into extended-connectivity fingerprints (ECFP4) using RDKit. Corresponding binary hepatotoxicity labels are retrieved from the toxicity database.

- Model Training: The dataset is split 80:20 into training and hold-out test sets. A GBM model (e.g., using

XGBoost) is trained using 5-fold cross-validation on the training set. Hyperparameters (learning rate, max depth, n_estimators) are optimized via Bayesian optimization. - Validation: Model performance is evaluated on the hold-out test set using AUC-ROC, precision, and recall metrics. Predictions for novel compounds are generated, and the top 100 predicted non-toxic compounds are advanced for in vitro validation.

Protocol 2: CV-Based Automated Cell Viability and Morphology Analysis

Aim: To implement a U-Net based pipeline for automated live/dead cell classification and morphological feature extraction from brightfield microscopy images.

Materials:

- Incubator-equipped microscope with automated stage

- Cell culture plates (96-well)

- Label-free or stain-based cell preparations

- Python with TensorFlow/Keras and OpenCV

Methodology:

- Image Acquisition: Acquire time-lapse brightfield images (20x magnification) from each well at defined intervals (e.g., every 4 hours) over 72 hours.

- Model Inference: Pass each image through a pre-trained U-Net model for semantic segmentation. The model outputs pixel-wise masks for "Live Cell," "Dead Cell," and "Background."

- Quantification & Feature Extraction: Calculate viability (%) as (Live Cell Pixels / Total Cell Pixels) * 100. Extract morphological features (area, circularity, texture) from the live cell masks for each well and time point.

- Dose-Response Analysis: For drug-treated wells, plot viability and morphological dynamics against compound concentration to derive IC50 values.

Protocol 3: RPA for Automated LIMS-to-ELN Data Pipeline

Aim: To create an RPA bot that transfers experimental results from the LIMS to the appropriate project folder in the ELN and triggers a report generation workflow.

Materials:

- Access to LIMS (e.g., LabVantage) and ELN (e.g., Benchling) with API/log-in credentials.

- RPA software platform (e.g., UiPath, Automatio).

Methodology:

- Bot Design: Configure the RPA bot to log into the LIMS at scheduled intervals (e.g., every hour). Program it to query for completed assay batches with a "Results Approved" status flag.

- Data Extraction & Transformation: For each completed batch, the bot extracts the structured result table, sample IDs, and assay metadata. It reformats this data into a pre-defined template (e.g., .csv or .xlsx).

- Automated Upload & Notification: The bot logs into the ELN, navigates to the specified project directory, and uploads the results file. It then populates a summary field in the ELN experiment page and sends an email notification to the lead scientist.

The Scientist's Toolkit

Table 4: Key Research Reagent Solutions for AI-Enhanced Laboratory Workflows

| Item | Function in AI-Enhanced Workflow |

|---|---|

| High-Content Imaging Systems (e.g., PerkinElmer Opera, Molecular Devices ImageXpress) | Generates the high-dimensional image data required for training and deploying computer vision models for phenotypic screening. |

| Liquid Handling Robots (e.g., Hamilton Microlab STAR, Tecan Fluent) | Provides precise, reproducible physical automation for sample preparation, enabling the generation of large, consistent datasets for ML model training. |

| Cloud Computing Credits (AWS, GCP, Azure) | Offers scalable computational power for training complex deep learning models and storing large-scale experimental datasets. |

| Integrated Lab Platform (e.g., Benchling, IDBS Polar) | Serves as a centralized digital hub (ELN/LIMS) that provides structured data inputs for RPA bots and generates the workflow data used for ML analysis. |

| Curated Public Datasets (e.g., ChEMBL, Cell Painting Gallery, Tox21) | Provide essential, high-quality labeled data for pre-training and validating machine learning models in a biological context. |

Visualizations

AI Lab Workflow Integration

Automated Experiment Cycle

Within the broader thesis on AI tools for automated laboratory workflows, the data pipeline represents the critical infrastructure. It transforms raw biological or chemical material into actionable, stored knowledge. This Application Note details the modern, integrated pipeline, emphasizing points of AI integration and automation for researchers and drug development professionals.

Sample Preparation & Acquisition

This initial phase converts a biological specimen or compound into a processable digital signal.

Key Protocol: Automated Nucleic Acid Extraction for NGS

- Objective: To obtain high-quality, sequencing-ready DNA/RNA from cell cultures using an automated liquid handler.

- Materials: Cultured cells, lysis buffer, binding beads, wash buffers, elution buffer, 96-well plate, magnetic stand module, robotic liquid handling platform (e.g., Hamilton Microlab STAR).

- Procedure:

- Lysis: Transfer 200 µL of cell sample to a deep-well plate. Add 200 µL lysis/binding buffer mix. Mix by pipetting.

- Binding: Add 50 µL of magnetic beads. Incubate for 5 minutes at room temperature. Engage magnetic module to capture beads.

- Washing: Remove supernatant. With magnet engaged, wash twice with 500 µL wash buffer 1, then once with 800 µL wash buffer 2.

- Elution: Air-dry beads for 5 minutes. Resuspend in 50 µL nuclease-free water. Incubate at 70°C for 5 minutes. Capture beads and transfer eluate to a new plate.

- AI Integration: Computer vision systems can monitor bead pelleting and supernatant clarity, dynamically adjusting wash times.

The Scientist's Toolkit: Sample Prep Reagents & Kits

| Item | Function & Key Feature |

|---|---|

| Magnetic Bead-Based Extraction Kit | Binds nucleic acids; amenable to high-throughput automation on magnetic handlers. |

| Multiplexed Assay Kits (e.g., for qPCR) | Allows simultaneous measurement of multiple targets from one sample, optimizing data density. |

| Cell Viability Stain with Fluorescent Readout | Enables automated, image-based cell counting and selection before processing. |

| Barcoded Liquid Reagent Reservoirs | Facilitates tracking and error-proofing by robotic systems. |

Data Generation & Instrumentation

Here, prepared samples are analyzed by instruments to generate primary digital data.

Quantitative Data: Throughput of Common Instruments

Table 1: Comparison of Data Generation Platforms

| Instrument Type | Typical Samples/Run | Data Volume Per Run | Primary Data Format |

|---|---|---|---|

| High-Throughput Sequencer (NovaSeq X) | 1-20 billion reads | 1.6 - 16 TB | FASTQ, BCL |

| High-Content Screener (ImageXpress) | 10 - 500 plates/day | 100 GB - 5 TB | TIFF, PNG, Metadata |

| LC-MS/MS for Proteomics | 100 - 1000 samples/day | 10 - 500 GB | .raw, .mzML |

| Automated Patch Clamp | Up to 10,000 cells/day | 1 - 100 GB | .abf, .dat |

Protocol: Automated High-Content Imaging Workflow

- Objective: To acquire and pre-process cellular images for phenotype analysis.

- Materials: 384-well assay plate, fluorescent probes, high-content imager (e.g., PerkinElmer Opera, ImageXpress), automated plate hotel.

- Procedure:

- Scheduling: Define plate layout, well types (controls, treatments), and imaging sites/well in the scheduler software.

- Acquisition: Automated loader places plate in imager. Using predefined channels (DAPI, FITC, TRITC), the system autofocuses and captures z-stacks.

- On-the-fly Preprocessing: Instrument software performs flat-field correction, background subtraction, and stitching.

- Transfer: Processed images and metadata are automatically transferred to a designated network storage path for downstream analysis.

Data Analysis & AI Processing

This is the core AI integration phase, where raw data is transformed into biological insights.

Diagram: AI-Enabled Analysis Workflow

AI Analysis Workflow for Lab Data

Key Analysis Protocols

- AI-Based Image Analysis (Cell Phenotyping): Preprocessed images are fed into a convolutional neural network (CNN) like ResNet or a U-Net for segmentation. The model identifies and classifies cells, quantifying fluorescence intensity, morphology, and count per well.

- NGS Variant Calling Pipeline: AI tools (e.g., DeepVariant) process aligned sequencing reads (BAM files) to call genetic variants with higher accuracy than traditional statistical methods, especially in low-coverage regions.

Data Storage & Management

The final, crucial phase ensures data integrity, accessibility, and FAIR (Findable, Accessible, Interoperable, Reusable) compliance.

Diagram: Hierarchical Laboratory Data Storage Architecture

Lab Data Storage Tiers and Flow

Protocol: Establishing an Automated Data Archival Rule

- Objective: To automatically move data from primary storage to long-term archive.

- Materials: Network-Attached Storage (NAS) system, object storage or tape archive, data management software (e.g., on-premise script, cloud lifecycle rule).

- Procedure:

- Define Policy: Criteria: Data in "/project/active/" older than 90 days since last access, with a completed analysis flag in the LIMS.

- Implement Script: Write a Python script using

osandshutillibraries (or use storage management software) to scan directories, check metadata, and move files. - Integrate with LIMS: Script queries LIMS API to confirm project status before moving.

- Log & Update: Script logs all moves in a database and updates the file path in the LIMS to point to the new archive location.

A seamless data pipeline, from sample prep to storage, is the backbone of modern automated research. Strategic integration of AI at the analysis stage and robust, automated data management protocols are essential for accelerating drug development and ensuring reproducible science within next-generation laboratories.

Current Adoption Trends in Biopharma and Academic Research Centers

Application Notes: AI-Driven Automation in Research Workflows

Recent industry analysis and surveys indicate a rapid, though uneven, adoption of AI and automation tools across biopharma and academia. The primary divergence lies in scale and strategic focus, while convergence is observed in the pursuit of foundational data infrastructure.

Table 1: Adoption Trends and Drivers (2023-2024)

| Trend Category | Biopharma Industry | Academic Research Centers |

|---|---|---|

| Primary Strategic Driver | Accelerated drug discovery & development; ROI on R&D investment. | Enhanced research reproducibility; enabling complex, multi-omics experiments. |

| Key Adoption Focus | Closed-loop systems for compound design, synthesis, and testing. High-throughput screening & clinical trial optimization. | Modular, open-source platforms for specific tasks (e.g., image analysis, single-cell sequencing). |

| Major Investment Area | Integrated AI/ML platforms (e.g., for target ID, biomarker discovery). Robotic cloud labs for distributed workflow execution. | Data generation standardization and FAIR (Findable, Accessible, Interoperable, Reusable) data management systems. |

| Top Reported Barrier | Data siloing & legacy system integration. High initial capital cost. | Lack of dedicated computational & engineering support staff. Funding cycles misaligned with software development. |

| Quantitative Metric | ~65% of top 20 pharma report active AI/automation alliances or in-house hubs. | ~40% of surveyed life science labs use some form of scripted/image analysis automation (up from ~22% in 2020). |

Table 2: Preferred Application Areas for Initial Automation

| Application Area | Biopharma Priority (High/Med/Low) | Academic Priority (High/Med/Low) | Common AI Tool Example |

|---|---|---|---|

| High-Content Screening Analysis | High | High | Deep learning models (CNNs) for phenotypic profiling. |

| Next-Generation Sequencing (NGS) Data Analysis | High | High | Automated variant calling & expression quantification pipelines. |

| Synthetic Route Planning & Chemistry | High | Medium | Retrospective synthesis AI (e.g., CASP tools). |

| Laboratory Inventory & Sample Management | Medium | Low | RFID/IoT-enabled freezer and liquid handling tracking. |

| In Silico Target Validation & Prioritization | High | Medium | Knowledge graphs integrating multi-omics and literature data. |

| Automated Protocol Generation & Execution | Medium (growing) | Low (but interest high) | Natural language to executable protocol translators. |

Experimental Protocol: Automated High-Content Screening (HCS) for Phenotypic Drug Discovery

This protocol details an AI-integrated workflow for label-free cell imaging and analysis, representative of trends toward streamlined, data-rich assays.

Title: Automated, Label-Free Cell Phenotyping Using AI-Driven Image Analysis

Objective: To automatically treat, image, and classify cultured cells based on morphological changes induced by compound libraries, minimizing manual staining and subjective analysis.

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in Protocol |

|---|---|

| Live-Cell Imaging Optimized Plates (e.g., 96-well µ-plate) | Provides optical clarity for high-resolution phase-contrast or DIC imaging. Coating (e.g., poly-D-lysine) ensures consistent cell adhesion. |

| CELLphenant SC Proliferation Media | Serum-free, phenol red-free medium formulated for sustained health during live imaging, reducing background fluorescence. |

| SynthoLipid 5000 Lipid Library | A defined library of synthetic lipids used as perturbagens to induce diverse, tractable morphological phenotypes for model training. |

| Cytoskeleton Fixative & Permeabilization Kit (Rapid) | For optional post-imaging fixation/staining to validate AI predictions. Contains gentle crosslinkers and detergents. |

| NucleoBright DNA Stain (Cell-Permeant) | Low-toxicity, blue-fluorescent stain for nuclei validation without interfering with prior live imaging. |

Materials & Equipment:

- Robotic liquid handler (e.g., Hamilton STARlet)

- Incubator-equipped, high-content live-cell imager (e.g., Molecular Devices ImageXpress Micro Confocal)

- High-performance computing cluster or cloud instance (e.g., AWS EC2 G4 instances)

- Software: Scheduling software (e.g., Green Button Go), Image analysis pipeline (CellProfiler v4.2+), ML classifier (TensorFlow/PyTorch).

Methodology:

Part A: Automated Cell Seeding & Treatment (Day 1)

- Plate Preparation: Using the liquid handler, dispense 80 µL of complete growth medium into each well of a 96-well imaging plate.

- Cell Seeding: Trypsinize and resuspend U2OS cells in fresh medium. Dilute to 1.5 x 10⁴ cells/mL. Dispense 100 µL of cell suspension (1,500 cells/well) into each well. Shake plates on orbital shaker (150 rpm, 1 min).

- Incubation: Place plates in a humidified incubator (37°C, 5% CO₂) for 20-24 hours to achieve ~40% confluence.

- Compound Addition (Automated): Prepare compound/library plates (e.g., SynthoLipid library) at 1000X final concentration in DMSO. Program liquid handler to: a. Retrieve cell plate from incubator stacker. b. Add 0.18 µL of compound per well to designated wells (n=4 replicates). Include DMSO-only vehicle controls. c. Return plate to incubator.

Part B: Live-Cell Imaging (Day 2)

- Imager Setup: Pre-warm imager chamber to 37°C with 5% CO₂ control. Set phase-contrast objectives (20x) and focusing system.

- Scheduled Acquisition: At 16 hours post-treatment, initiate automated imaging. Acquire 9 non-overlapping fields per well. Save images in OME-TIFF format with metadata (well ID, treatment, timestamp).

Part C: AI-Enhanced Image Analysis (Post-Acquisition)

- Preprocessing Pipeline (CellProfiler):

- Module 1:

Images- Load OME-TIFF stacks. - Module 2:

CorrectIlluminationCalculate- Estimate background illumination. - Module 3:

CorrectIlluminationApply- Flatten image background. - Module 4:

IdentifyPrimaryObjects- Detect cells using adaptive Otsu thresholding (diameter 30-100 pixels). - Module 5:

MeasureObjectSizeShape&MeasureTexture- Extract ~500 morphological features (e.g., Area, Eccentricity, Zernike moments) per cell. - Output: CSV file of single-cell feature data.

- Module 1:

Phenotype Classification (Python Script):

Hit Identification: Wells with a statistically significant shift (p<0.01, Chi-square test) from vehicle control phenotype profiles are flagged for validation.

Part D: Validation & Secondary Assay Triaging (Optional Day 3)

- Fixation: Using an automated handler, add 50 µL of 4% PFA (in PBS) to each well for final 15 min fixation.

- Staining: Permeabilize (0.1% Triton X-100, 10 min), stain with NucleoBright (1:2000, 20 min), wash.

- Re-image: Acquire fluorescent nuclei images to validate cell count and segmentation accuracy from phase-contrast data.

Visualization: AI-Integrated Laboratory Workflow Diagram

Diagram Title: AI-Augmented Drug Screening Workflow

Visualization: Signaling Pathway Analysis via Knowledge Graph

Diagram Title: AI-Contextualized PI3K-MAPK Crosstalk Pathway

Implementing AI: A Step-by-Step Guide to Key Laboratory Applications

Within the broader thesis on AI tools for automated laboratory workflows, the integration of artificial intelligence into High-Throughput Screening (HTS) image analysis represents a paradigm shift. Traditional HTS, which generates millions of cellular images, has been bottlenecked by manual or semi-automated analysis. AI, particularly deep learning (DL) models like convolutional neural networks (CNNs), automates the extraction of complex morphological phenotypes, enabling unbiased, high-content hit identification. This directly enhances the efficiency, reproducibility, and predictive power of drug discovery pipelines, moving labs toward fully autonomous experimental cycles.

AI-Enhanced HTS Workflow: Protocol and Application Notes

This protocol outlines an end-to-end workflow for applying AI to HTS image analysis for hit identification in a phenotypic screen.

Protocol Title: AI-Driven Morphological Profiling for Hit Identification in a Phenotypic HTS Campaign.

Objective: To identify compounds that induce a target phenotypic response (e.g., altered nuclear morphology, cytoskeletal reorganization) from a large-scale image-based screen using a trained DL model.

Materials & Pre-Screening Setup:

- Cell Line: Genetically engineered U2OS osteosarcoma cell line expressing a fluorescent nuclear marker (H2B-GFP).

- Compound Library: A diverse small-molecule library (>100,000 compounds) plated in 384-well format.

- Controls: Positive control (e.g., Actinomycin D for nuclear fragmentation), negative control (DMSO vehicle), neutral control (unrelated bioactive compound).

- Imaging Platform: High-content confocal imager (e.g., Yokogawa CV8000, PerkinElmer Opera Phenix). 20x objective. 4 fields per well.

- AI Infrastructure: GPU cluster (NVIDIA V100/A100) with deep learning frameworks (PyTorch, TensorFlow) and image analysis libraries (CellProfiler, DeepCell, AICSImageIO).

Experimental Procedure:

- Cell Seeding & Treatment: Seed U2OS H2B-GFP cells at 2,000 cells/well in 384-well plates. Incubate for 24 hrs. Treat with compound library (1 µM final concentration) for 48 hrs using an acoustic liquid handler.

- Fixation & Staining: Fix cells with 4% PFA, permeabilize with 0.1% Triton X-100, and stain F-actin with phalloidin conjugated to Alexa Fluor 568.

- High-Content Imaging: Image each well automatically across GFP and TRITC channels. Images are saved in a standardized format (e.g., OME-TIFF) with full metadata.

- AI Model Application:

- Preprocessing: Ingest images. Apply illumination correction and flat-field correction using control well data.

- Segmentation: Input the nuclear channel (GFP) into a pre-trained U-Net model for precise nuclear segmentation. Output is a mask of each cell nucleus.

- Feature Extraction: Using the nuclear mask, a CNN-based feature extractor (e.g., ResNet50) pre-trained on ImageNet and fine-tuned on biological images generates a 512-dimensional morphological profile (embedding vector) for each cell.

- Phenotype Classification: A classifier head maps the embeddings to predefined phenotypic classes (e.g., "Normal," "Fragmented," "Enlarged," "Condensed").

- Hit Identification: Wells are ranked based on the Z-score of the fraction of cells exhibiting the target phenotype (e.g., nuclear fragmentation) relative to the negative control plate.

- Primary Hit Threshold: Wells with Z-score > 3 and a phenotypic fraction > 25% are flagged.

- Hit Confirmation: Primary hits are re-tested in a dose-response format (8-point, 1:3 dilution series). The dose-dependent induction of the phenotype is assessed to confirm efficacy and begin estimating potency (EC50).

Data Presentation: Performance Metrics of AI vs. Traditional Analysis

A recent benchmark study compared a DL pipeline to a traditional hand-crafted feature approach in a cytotoxicity screen.

Table 1: Comparative Performance of AI vs. Traditional Image Analysis in a Cytotoxicity HTS

| Metric | Traditional (Hand-crafted Features) | AI (Deep Learning CNN) | Notes |

|---|---|---|---|

| Analysis Throughput | ~120 wells/hour/CPU core | ~1,200 wells/hour/GPU | AI leverages parallel processing on GPU. |

| Segmentation Accuracy (mAP) | 0.76 | 0.94 | Mean Average Precision (mAP) on held-out test set. |

| Hit Recall Rate | 82% | 96% | % of known active compounds correctly identified. |

| False Positive Rate | 8.5% | 2.1% | % of inactive compounds incorrectly flagged as hits. |

| Morphological Features Extracted | 150 (pre-defined) | 512+ (data-driven) | AI extracts abstract, informative features. |

| Adaptation to New Phenotype | Requires manual feature re-engineering | Transfer learning with ~10,000 new images | AI is more adaptable with sufficient new data. |

Visualizing the AI-HTS Workflow and Key Pathway

Diagram 1: AI-Powered HTS Image Analysis Workflow

Diagram 2: Key Apoptotic Pathway for a Nuclear Fragmentation Phenotype

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents and Materials for AI-Driven HTS

| Item Name | Supplier Examples | Function in AI-HTS Workflow |

|---|---|---|

| Fluorescent Cell Line (H2B-GFP) | ATCC, Sigma-Aldrich | Provides a consistent, bright nuclear label for robust AI-based segmentation. |

| Phalloidin Conjugates (e.g., Alexa Fluor 568) | Thermo Fisher, Cytoskeleton Inc. | Labels F-actin for morphological context, enabling multiparametric phenotypic analysis. |

| Validated Compound Library (e.g., LOPAC) | Sigma-Aldrich, Selleckchem | Provides a high-quality, annotated small-molecule set for model training and screening. |

| OME-TIFF Compatible Imaging Plates (384-well) | Corning, Greiner Bio-One | Ensures image data is saved with rich, standardized metadata for AI pipeline ingestion. |

| Cell Painting Assay Kit | Revvity | Standardized cocktail of dyes to generate rich morphological profiles for AI training. |

| DL Model Weights (Pre-trained BioImage Models) | Hugging Face, BioImage.IO | Accelerates development by providing a starting point for transfer learning. |

| GPU-Accelerated Cloud Platform Credits | AWS (EC2 P3/G4), Google Cloud (GPU VMs) | Provides scalable computational power for model training and large-scale inference. |

Within a thesis on AI tools for automated laboratory workflows, the integration of automated NGS variant calling and interpretation represents a paradigm shift. This pipeline transforms raw sequencing data into actionable clinical or research insights with minimal manual intervention, enhancing reproducibility, scalability, and speed in genomic medicine and drug target discovery.

Key Application Areas:

- Oncology: Identification of somatic tumor mutations for therapy selection (e.g., matching variants in EGFR, BRCA1/2 to targeted therapies).

- Rare Disease Diagnosis: Detection of germline pathogenic variants in Mendelian disorders.

- Pharmacogenomics: Determining allele status for genes like CYP2C19 to predict drug metabolism.

- Microbial Genomics: Variant calling for pathogen strain typing and antimicrobial resistance profiling.

Performance Metrics of Current AI-Enhanced Tools (Representative Data):

Table 1: Comparison of Automated Variant Calling Pipelines & AI Interpretation Tools

| Tool/Pipeline | Type | Key AI/Algorithm | Reported Sensitivity (SNV) | Reported Precision | Primary Use Case |

|---|---|---|---|---|---|

| DeepVariant | Variant Caller | Convolutional Neural Network (CNN) | >99.7% (PCR-Free WGS) | >99.9% | Germline & Somatic SNVs/Indels |

| Clair | Variant Caller | Deep Neural Network (DNN) | 99.85% (WGS) | 99.98% | Germline SNVs/Indels |

| DRAGEN | Accelerated Pipeline | FPGA-Hardware Optimized | 99.6% (WGS) | 99.96% | Germline & Somatic, Tumor-Normal |

| IBM Watson for Genomics | Interpretation | NLP, Machine Learning | N/A | N/A | Therapy-relevant variant ranking |

| Moon | Interpretation | Composite AI, Knowledge Graphs | N/A | >95% (Diagnostic Yield) | Rare disease variant prioritization |

Core Experimental Protocols

Protocol 1: Automated End-to-End Variant Calling from FASTQ to VCF Objective: To generate a high-confidence set of germline variants (SNVs and Indels) from whole genome sequencing data using a fully automated, AI-integrated workflow.

- Input: Paired-end FASTQ files, reference genome (GRCh38/hg38), known variant databases (e.g., gnomAD, dbSNP).

- Quality Control & Trimming:

- Tool: FastQC (v0.12.0) & Trimmomatic (v0.39).

- Command:

java -jar trimmomatic.jar PE -phred33 input_R1.fq.gz input_R2.fq.gz output_R1_paired.fq.gz output_R1_unpaired.fq.gz output_R2_paired.fq.gz output_R2_unpaired.fq.gz ILLUMINACLIP:adapters.fa:2:30:10 LEADING:3 TRAILING:3 SLIDINGWINDOW:4:15 MINLEN:36

- Alignment:

- Tool: BWA-MEM2 (v2.2.1).

- Command:

bwa-mem2 mem -t 8 -R '@RG\tID:sample\tSM:sample\tPL:ILLUMINA' GRCh38.fasta output_R1_paired.fq.gz output_R2_paired.fq.gz > aligned.sam

- Post-Alignment Processing (BAM Generation):

- Sort & Convert:

samtools sort -@8 -o sorted.bam aligned.sam - Mark Duplicates: Use GATK (v4.3)

MarkDuplicatesSpark.

- Sort & Convert:

- Variant Calling with AI Tool:

- Tool: DeepVariant (v1.5.0).

- Command:

mkdir -p deepvariant_output && docker run -v "/data:/data" google/deepvariant:1.5.0 /opt/deepvariant/bin/run_deepvariant --model_type=WGS --ref=/data/GRCh38.fasta --reads=/data/sorted.bam --output_vcf=/data/deepvariant_output/output.vcf.gz --num_shards=8

- Variant Quality Score Recalibration (VQSR):

- Tool: GATK

VariantRecalibrator&ApplyVQSRusing known variant sites as training sets.

- Tool: GATK

- Output: A final, filtered VCF file ready for annotation and interpretation.

Protocol 2: AI-Driven Genomic Interpretation for Rare Diseases Objective: To prioritize likely pathogenic variants from a VCF file in a proband-only or trio analysis context.

- Input: Annotated VCF file (e.g., from ANNOVAR, VEP), patient phenotype (HPO terms).

- Variant Annotation & Filtering:

- Tool: Geneyx Analysis or similar.

- Step: Filter variants based on population frequency (<1% in gnomAD), predicted impact (missense, loss-of-function, splicing), and inheritance mode compatible with phenotype.

- AI-Powered Prioritization:

- Tool: Integration with Moon (DiCE/ICE algorithms) or Exomiser.

- Method: Upload filtered variant list and HPO terms. The AI scores variants by integrating gene-phenotype association scores (from knowledge graphs), variant pathogenicity predictions (e.g., CADD, REVEL), and cross-species conservation data.

- Review & Reporting:

- Manually inspect top-ranked variants (e.g., top 5-10) in a genome browser (IGV). Confirm segregation in family if data available.

- Classify variants according to ACMG/AMP guidelines. Generate a clinical report highlighting candidate variants.

Visualized Workflows and Pathways

Automated NGS Variant Calling Pipeline

AI-Driven Genomic Variant Interpretation

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents & Materials for NGS Variant Calling Workflows

| Item / Kit | Function & Explanation |

|---|---|

| Illumina DNA Prep with Enrichment | Library preparation kit for targeted sequencing; incorporates enzymatic fragmentation and tagmentation for streamlined automation. |

| KAPA HyperPrep or HyperPlus Kit | Robust library prep kit for whole genome or exome sequencing, compatible with low-input and automated liquid handlers. |

| IDT xGen Pan-Cancer Panel | A targeted hybridization capture panel for uniform coverage of cancer-related genes, ensuring high sensitivity for somatic variant detection. |

| Twist Human Core Exome | A high-performance, comprehensive exome capture panel with uniform coverage, critical for germline rare disease analysis. |

| PhiX Control v3 | Sequencing run quality control; provides a balanced nucleotide composition for cluster generation and base calling calibration. |

| Bio-Rad ddPCR Mutation Detection Assays | Orthogonal validation of critical NGS-called variants (e.g., low-frequency SNVs); provides absolute quantification without standards. |

| Sera-Mag SpeedBeads | Magnetic carboxylate-modified particles used for automated, bead-based clean-up and size selection steps during library prep. |

Application Notes

The integration of Artificial Intelligence (AI) into synthetic biology and CRISPR workflows represents a paradigm shift, addressing critical bottlenecks in experimental design and guide RNA (gRNA) selection. Within the broader thesis of AI for automated laboratory workflows, these tools transition the researcher from a manual executor to a strategic overseer, optimizing resource allocation and accelerating the design-build-test-learn cycle.

AI-Assisted Design of Experiments (DOE): Traditional DOE for multiplexed CRISPR screens or metabolic engineering is combinatorially complex. AI, particularly Bayesian optimization and active learning algorithms, can model high-dimensional parameter spaces (e.g., sgRNA combinations, inducer concentrations, growth conditions) to predict optimal experimental setups that maximize information gain. This reduces the number of required physical experiments by 50-70% while identifying non-linear interactions missed by classical approaches.

AI-Driven gRNA Selection: The efficacy of CRISPR-mediated editing is highly dependent on gRNA specificity and on-target activity. AI models (e.g., convolutional neural networks, gradient boosting machines) now integrate genomic context, chromatin accessibility, and epigenetic markers to predict cutting efficiency and off-target effects with superior accuracy compared to first-generation rules-based algorithms.

Table 1: Quantitative Performance Comparison of gRNA Design Tools

| Tool Name | AI Model Type | Reported On-Target Prediction Accuracy (AUC) | Off-Target Sites Considered | Key Predictive Features |

|---|---|---|---|---|

| DeepCRISPR | Convolutional Neural Network (CNN) | 0.92 | Genome-wide | Sequence, Epigenetic features |

| Rule Set 2 | Gradient Boosting Machine | 0.89 | Mismatch-based | Sequence, Thermodynamics |

| CRISPRscan | Random Forest | 0.86 | Local context | Sequence, Genomic context |

| CRISPick | Ensemble Model | 0.91 | CFD-specific | Sequence, Chromatin State |

Table 2: Impact of AI-DOE on Experimental Efficiency

| Parameter | Traditional DOE | AI-Assisted DOE | Efficiency Gain |

|---|---|---|---|

| Experiments to Optimum | 50-100 | 15-30 | ~70% reduction |

| Factor Interactions Identified | Main & 2-way | Up to 4-way | More complex insight |

| Resource Utilization | High | Optimized | 40-60% cost saving |

| Project Timeline | 12-16 weeks | 4-6 weeks | ~3x acceleration |

Protocols

Protocol 1: AI-Guided Design of a CRISPRa Knock-In Screen

Objective: To activate endogenous gene expression via CRISPRa (dCas9-VPR) and screen for phenotypic changes, using AI to select gRNAs and design a minimal, maximally informative experimental matrix.

Materials: See "The Scientist's Toolkit" below.

Methodology:

- Define Objective: Specify target gene list (e.g., 100 metabolic pathway genes) and desired readout (e.g., fluorescence, growth rate).

- AI gRNA Selection:

- Input target gene sequences into an AI-powered platform (e.g., CRISPick, CHOPCHOP v3).

- Set parameters: gRNA length (20-23 nt), exclude SNPs, prioritize open chromatin regions.

- The AI model ranks 5 gRNAs per gene based on predicted on-target activity and off-target score.

- AI Experimental Design:

- Input parameters into an AI-DOE platform (e.g., Dragonfly, Sherpa): 500 candidate gRNAs, 96-well plate format, budget for 50 constructs.

- The AI uses Bayesian optimization to output a 50-gRNA subset and experimental plate layout that maximizes coverage and minimizes confounding positional effects.

- Wet-Lab Execution:

- Synthesize and clone the AI-selected gRNAs into the CRISPRa lentiviral vector.

- Produce lentivirus and transduce target cells in the AI-prescribed layout.

- Assay phenotypic readout after 72-96 hours.

- Data Integration & Model Refinement:

- Collect readout data and upload back to the AI-DOE platform.

- The model analyzes results, identifies hit genes, and may suggest a subsequent, refined experimental round to deconvolve interactions.

Protocol 2: High-Throughput Validation of AI-Predicted gRNA Efficacy

Objective: Empirically validate the on-target editing efficiency of AI-selected versus conventionally selected gRNAs.

Materials: See "The Scientist's Toolkit" below.

Methodology:

- gRNA Pool Design:

- For 20 target loci, obtain: a) 2 top-ranked gRNAs from an AI tool (DeepCRISPR), b) 2 top-ranked gRNAs from a traditional tool (e.g., Zhang Lab CRISPR Design Tool). Total: 80 gRNAs.

- Library Construction & Delivery:

- Synthesize oligo pool containing all 80 gRNA sequences.

- Clone pool into a lentiviral Cas9/gRNA backbone (e.g., lentiCRISPR v2).

- Transduce a polyclonal population of HEK293T cells stably expressing Cas9 at low MOI (<0.3).

- Next-Generation Sequencing (NGS) Analysis:

- Harvest genomic DNA from cells 7 days post-transduction.

- PCR-amplify target regions and subject to NGS (Illumina MiSeq, 2x250 bp).

- Efficiency Quantification:

- Process sequencing data with a CRISPR analysis tool (e.g., CRISPResso2).

- Calculate indel frequency (%) at each target locus for each gRNA.

- Validation:

- Compare mean indel frequency between AI-selected and traditionally-selected gRNA groups using a paired t-test.

- Corrogate predicted efficiency scores from each tool with measured indel frequencies using Pearson correlation.

Diagrams

AI-Driven CRISPR Screen Workflow

AI Model for gRNA Efficacy Prediction

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item | Function & Rationale |

|---|---|

| AI/DOE Software Platform (e.g., Benchling DOE, IDT CRISPR-Cas9 design tool, custom Dragonfly/Bayesian scripts) | Central hub for design. Integrates gRNA prediction, designs optimal experimental matrices, and manages sample tracking. |

| High-Fidelity DNA Polymerase (e.g., Q5, Phusion) | Essential for error-free amplification of gRNA expression cassettes and target loci for NGS validation. |

| Next-Generation Sequencing Service/Kit (e.g., Illumina Amplicon-EZ) | Provides quantitative, high-depth sequencing data for indel analysis and off-target profiling. |

| CRISPR Analysis Software (e.g., CRISPResso2, Cas-Analyzer) | Specialized bioinformatics tool to process NGS data and quantify editing efficiencies and outcomes. |

| Lentiviral Packaging System (e.g., psPAX2, pMD2.G plasmids) | Enables efficient, stable delivery of Cas9 and gRNA libraries into hard-to-transfect cell types. |

| Nucleofection System (e.g., Lonza 4D-Nucleofector) | For high-efficiency, transient delivery of RNP complexes in primary or sensitive cell lines. |

| Validated Anti-Cas9 Antibody | Critical for confirming Cas9 protein expression via western blot in stable cell line generation. |

| Fluorophore-Conjugated tracrRNA (e.g., Cy3-tracrRNA) | Allows visualization of RNP complex delivery and transfection efficiency via flow cytometry or microscopy. |

| Genomic DNA Cleanup Kit (Magnetic Bead-based) | For rapid, high-quality gDNA extraction prior to PCR for NGS library prep. |

| Synthetic gRNA or crRNA Pool | Commercially synthesized, sequence-verified oligo pool representing the AI-designed library. |

Within a thesis on AI tools for automated laboratory workflows, this application note details the integration of predictive models into automated platforms for early-stage drug discovery. The focus is on high-throughput virtual screening (HTVS) and the prediction of Absorption, Distribution, Metabolism, Excretion, and Toxicity (ADMET) properties. These in silico models act as intelligent filters within automated robotic systems, prioritizing compounds for synthesis and physical testing, thereby accelerating the lead identification and optimization cycle while reducing resource expenditure.

Application Notes: Integrating Predictive Models into Automated Workflows

2.1. Virtual Screening Cascade An AI-driven virtual screening cascade is deployed prior to any wet-lab experimentation. This typically involves:

- Ultra-Large Library Screening (10^6-10^12 compounds): Using fast, structure-based (e.g., docking) or ligand-based (e.g., pharmacophore, 2D similarity) models to select a subset for more detailed evaluation.

- Focused Library Evaluation (10^4-10^5 compounds): Applying more computationally intensive models, such as molecular dynamics (MD) simulations or advanced machine learning (ML) scoring functions, to assess binding affinity and pose stability.

- ADMET Prediction (Top 10^3-10^4 compounds): Subjecting the top candidates to a battery of ML models predicting key pharmacokinetic and safety endpoints.

2.2. Key Predictive ADMET Endpoints The following ADMET properties are critical for early-stage prediction and are commonly integrated into automated decision trees:

| Property | Typical Predictive Model | Common Experimental Assay | Impact on Progression |

|---|---|---|---|

| Aqueous Solubility | QSPR/Random Forest | Kinetic/Equilibrium Solubility (pH 7.4) | Dictates formulation strategy and bioavailability. |

| Caco-2 Permeability | Gradient Boosting Machine (GBM) | Caco-2 monolayer assay | Predicts intestinal absorption. |

| Human Liver Microsomal (HLM) Stability | Support Vector Machine (SVM) | In vitro metabolic stability assay | Indicates potential for rapid hepatic clearance. |

| CYP450 Inhibition (2D6, 3A4) | Deep Neural Network (DNN) | Fluorescence/LC-MS-based inhibition assay | Flags drug-drug interaction risks. |

| hERG Inhibition | Ensemble Classifier (e.g., XGBoost) | Patch-clamp electrophysiology | Primary cardiotoxicity liability screening. |

| AMES Mutagenicity | Graph Neural Network (GNN) | Bacterial reverse mutation assay | Identifies genotoxic potential. |

Table 1: Core ADMET properties predicted by AI models to triage compounds in automated workflows.

2.3. Quantitative Performance of State-of-the-Art Models Recent benchmarks (2023-2024) on public datasets highlight the predictive performance achievable for key endpoints.

| Model/Endpoint | Dataset | Algorithm | Reported Metric (Mean ± Std Dev) |

|---|---|---|---|

| Passive Caco-2 Permeability | Caco-2 Data | Directed Message Passing Neural Network | Accuracy: 0.87 ± 0.02, AUC-ROC: 0.93 ± 0.01 |

| hERG Inhibition | hERG Central | Attention-Based Graph Net | BA: 0.83 ± 0.03, MCC: 0.65 ± 0.04 |

| Hepatotoxicity | Tox21 | Multitask DNN | Concordance: 0.80 ± 0.02, Sensitivity: 0.76 ± 0.04 |

| CYP3A4 Inhibition | PubChem Bioassay | Extreme Gradient Boosting (XGBoost) | Precision: 0.89 ± 0.02, Recall: 0.85 ± 0.03 |

Table 2: Performance metrics for selected predictive ADMET models. BA = Balanced Accuracy, MCC = Matthews Correlation Coefficient.

Experimental Protocols

Protocol 1: Implementation of an Integrated AI-Driven Screening Workflow

Objective: To computationally screen a virtual library of 1 million compounds against a protein target and prioritize the top 500 for synthesis based on combined potency and ADMET predictions.

Materials (Research Reagent Solutions & Essential Software):

| Item | Function/Description |

|---|---|

| Virtual Compound Library (e.g., Enamine REAL, ZINC) | Source of synthetically accessible molecules for virtual screening. |

| Target Protein Structure (PDB format) | High-resolution 3D structure for structure-based docking. |

| Molecular Docking Software (e.g., AutoDock-GPU, FRED) | Rapidly predicts binding poses and scores for millions of compounds. |

| ADMET Prediction Platform (e.g., ADMETLab 3.0, pkCSM) | Web-based or local API for batch prediction of ADMET properties. |

| Automation Scripting (Python/R) | Custom scripts to manage data flow between software modules and apply decision rules. |

| Laboratory Information Management System (LIMS) | Tracks computational predictions and links to subsequent synthesis/assay requests. |

Methodology:

- Library Preparation: Standardize the virtual library (remove salts, neutralize charges, generate tautomers/protonation states at pH 7.4). Generate 3D conformers for each molecule.

- High-Throughput Docking: Dock the entire prepared library into the defined binding site of the target protein using accelerated docking software on a GPU cluster. Retain the top 50,000 compounds based on docking score.

- ADMET Filtering: Submit the SMILES strings of the top 50,000 compounds to a batch ADMET prediction service. Apply the following sequential filters:

- Filter 1 (Solubility & Permeability): LogS > -5.0 AND Predicted Caco-2 Papp > 5 * 10^-6 cm/s.

- Filter 2 (Metabolism & Toxicity): NOT Predicted hERG inhibitor (pIC50 < 5) AND NOT Predicted Ames mutagenic.

- Filter 3 (Drug-likeness): Passes at least 2 of 3 common rules (Lipinski, Ghose, Veber).

- Consensus Ranking: For compounds passing all filters, generate a composite score:

Rank = 0.6*(Normalized Docking Score) + 0.4*(Normalized ADMET Profile Score). Sort by this rank. - Output & LIMS Integration: Export the top 500 ranked compounds, including their structures, predicted properties, and sourcing information, as a request batch to the LIMS, triggering automated synthesis or procurement protocols.

Protocol 2: Experimental Validation of Predicted CYP3A4 Inhibition

Objective: To experimentally validate the in silico predictions for CYP3A4 inhibition for 50 selected compounds using a fluorescence-based high-throughput assay.

Materials (Research Reagent Solutions):

| Item | Function/Description |

|---|---|

| Human CYP3A4 Enzyme + P450 Reductase | Recombinant enzyme system for metabolic reactions. |

| Fluorogenic Substrate (e.g., 7-Benzyloxy-4-(trifluoromethyl)-coumarin, BFC) | Substrate metabolized by CYP3A4 to a fluorescent product. |

| Positive Control Inhibitor (Ketoconazole) | Known potent CYP3A4 inhibitor for assay validation. |

| Dimethyl Sulfoxide (DMSO), ≥99.9% | Solvent for compound stock solutions. |

| Potassium Phosphate Buffer (100 mM, pH 7.4) | Reaction buffer to maintain physiological pH. |

| NADPH Regenerating System | Provides the essential cofactor NADPH for CYP450 activity. |

| 384-Well Black, Clear-Bottom Microplates | Plate format for fluorescence reading. |

| Automated Liquid Handler | For precise, high-throughput reagent and compound dispensing. |

| Fluorescence Microplate Reader | To measure kinetic fluorescence increase (Ex/Em ~409/530 nm). |

Methodology:

- Compound Preparation: Prepare 10 mM stock solutions of test compounds and ketoconazole in DMSO. Using an automated liquid handler, serially dilute in DMSO and then transfer to assay plates such that the final DMSO concentration is 1% (v/v) in all wells.

- Assay Assembly (Final 50 µL volume): To each well, sequentially add:

- 25 µL of potassium phosphate buffer containing CYP3A4 enzyme (final 10 nM).

- 10 µL of diluted compound or controls (DMSO for 100% activity control).

- Pre-incubate plate for 10 minutes at 37°C.

- Reaction Initiation: Add 15 µL of a master mix containing the NADPH regenerating system and the fluorogenic substrate BFC (final 50 µM). Start kinetic fluorescence measurement immediately (1-minute intervals for 30 minutes).

- Data Analysis: Calculate the initial linear reaction velocity (V) for each well. Determine percent inhibition:

% Inhibition = [1 - (V_inhibitor / V_DMSO_control)] * 100. Fit dose-response curves to determine IC50 values. - Model Validation: Compare experimental IC50 values with model-predicted classes (Inhibitor/Non-Inhibitor). Calculate validation metrics (accuracy, precision, recall) to refine the predictive model.

Visualization: Workflows and Pathways

Diagram Title: AI-Driven Automated Drug Discovery Cycle (60 chars)

Diagram Title: Drug ADMET Pathway & AI Prediction Points (64 chars)

Integrating AI with LIMS and ELN Systems for End-to-End Workflow Management

Within the broader thesis on AI tools for automated laboratory workflows, this application note examines the integration of specialized Artificial Intelligence (AI) models with Laboratory Information Management Systems (LIMS) and Electronic Laboratory Notebooks (ELN) to create a seamless, data-driven research continuum. The synergy of these systems addresses critical bottlenecks in data capture, analysis, and decision-making, particularly in drug development. By embedding AI directly into the data and process fabric of the laboratory, researchers can transition from reactive data review to proactive, predictive workflow management.

Key Integration Points and Quantitative Benefits

Internet search results (2023-2024) from industry white papers and vendor case studies indicate measurable improvements from AI-LIMS-ELN integration. Key metrics are summarized below.

Table 1: Quantitative Impact of AI Integration on Laboratory Workflows

| Metric Category | Baseline (No AI Integration) | With AI-LIMS-ELN Integration | Data Source / Study Context |

|---|---|---|---|

| Data Entry & Annotation Time | 100% (Manual entry) | Reduced by 50-70% | Pharma R&D ELN Automation Pilot |

| Experimental Design Cycle Time | 7-14 days | Reduced to 2-5 days | AI-assisted design & reagent allocation |

| Data Retrieval & Compilation Time | Hours per request | Minutes via natural language query | LIMS with AI-powered search interface |

| Anomaly/Outlier Detection Rate | Manual review (<30% caught) | Automated detection (>95% caught) | QC data stream analysis in manufacturing |

| Predictive Asset Maintenance | Scheduled or reactive | 85-90% prediction accuracy | Instrument IoT data fed to AI via LIMS |

Application Note: AI-Driven Predictive Reagent Management

Context: A common inefficiency in drug discovery is the interruption of assay workflows due to depleted or suboptimal reagents. This protocol details the integration of an AI consumption forecast model with LIMS inventory and ELN experimental schedules.

3.1. Objective To proactively maintain critical reagent stocks by predicting usage patterns, thereby preventing workflow delays and ensuring assay consistency.

3.2. Protocol: Implementing the Predictive Management System

Step 1: Data Pipeline Establishment

- Action: Configure the LIMS API to export structured data streams to a secure cloud database. Required data includes:

- Reagent Master Data: Catalog ID, lot number, storage location, shelf-life.

- Transactional Data: Check-in/check-out events, quantities used (linked to ELN experiment ID), remaining volume.

- Experimental Schedule: Future assay plans from the ELN (assay type, projected start date, scientist).

- Tools: LIMS/ELN RESTful APIs, Cloud storage (e.g., AWS S3, Azure Blob).

Step 2: AI Model Training & Deployment

- Action: Train a time-series forecasting model (e.g., Prophet or LSTM network) using historical 24-month consumption data.

- Features: Day of week, assay type frequency (from ELN), project phase, lead scientist.

- Target Variable: Daily volume consumed per reagent category.

- Validation: Perform back-testing on the most recent 6 months of data. Deploy the validated model as a containerized microservice (e.g., using Docker) on a cloud platform.

- Tools: Python (pandas, scikit-learn, PyTorch/TensorFlow), Docker, Kubernetes.

Step 3: Integration & Alerting Workflow

- Action: Establish a bidirectional link.

- The AI service pulls daily inventory snapshots from LIMS.

- It pulls the upcoming 4-week experimental calendar from the ELN.

- It runs a daily forecast, calculating the predicted depletion date for each critical reagent.

- If the depletion date falls before the next scheduled delivery or within the lead time + safety margin, the AI service posts an alert directly into the LIMS as a pending action for the lab manager and triggers an email notification.

- The recommendation for reorder (item, quantity, urgency) is logged as a timestamped entry in the ELN's project management module.

- Tools: Custom integration middleware (e.g., using Python scripts or low-code platforms like MuleSoft), SMTP for email, LIMS/ELN API for posting alerts.

Step 4: Validation & Refinement

- Action: Run a 3-month pilot on 5 high-value reagent groups (e.g., kinases, cytokines, assay kits). Track:

- Number of stock-out events pre- and post-integration.

- Time saved in weekly manual inventory checks.

- Adherence to forecast (Mean Absolute Percentage Error).

- Refinement: Retrain model monthly with new data to account for changing research priorities.

Visualizing the Integrated System Architecture

Title: AI-LIMS-ELN Integration Data Flow

The Scientist's Toolkit: Key Research Reagent Solutions

The successful implementation of AI-integrated workflows relies on consistent, trackable materials.

Table 2: Essential Reagents & Materials for Traceable Workflows

| Item | Function & Relevance to AI Integration |

|---|---|

| 2D Barcoded Tubes/Plates | Enables automated, error-free sample tracking by LIMS via handheld or plate readers. Provides the critical link between physical sample and digital record. |

| RFID-Enabled Asset Tags | Allows AI-driven predictive maintenance models to monitor instrument location, usage hours, and calibrations via LIMS-integrated IoT sensors. |

| Standardized Assay Kits with Digital LOTs | Kits supplied with digital certificates of analysis (CoA) allow LIMS to auto-populate performance specs. AI uses this baseline for outlier detection in resulting data. |

| Mobile Lab Scanning App | Bridges physical and digital worlds. Scientists scan barcodes to log actions directly to ELN/LIMS, providing real-time data for AI consumption models. |

| Cloud-Enabled Analytical Instruments | Instruments that natively push raw data and metadata to LIMS/Cloud storage, creating the automated data pipeline required for AI model input. |

Protocol: Automated Experimental Data Validation & Annotation

6.1. Objective To automatically validate incoming instrument data against pre-defined QC rules, flag anomalies, and suggest annotations for the ELN, reducing manual review time.

6.2. Detailed Methodology

Step 1: Define QC Rules & Metadata Schema in LIMS

- Create digital SOPs in the LIMS that define, for each assay type:

- Acceptance Ranges: For controls, standards (e.g., Z'-factor > 0.5, CV < 20%).

- Required Metadata: Instrument serial number, analyst ID, reagent lot numbers.

- Configure the LIMS to enforce completion of these fields upon data upload.

Step 2: Deploy AI Validation Microservice

- Develop a validation script (e.g., in Python) that is triggered automatically upon data file arrival in the LIMS designated folder.

- Logic:

- Parse the raw data file (e.g., .csv, .xlsx) and extract results and metadata.

- Cross-reference the assay type with the QC rule set from Step 1.

- Calculate key QC metrics.

- Apply a simple rule-based AI (or a trained classifier for complex patterns) to assess "PASS/FLAG/FAIL."

- If PASS: Auto-generate a summary annotation (e.g., "Assay QC passed. Z' = 0.62. All controls within range.") and post it to the corresponding ELN experiment page via API.

- If FLAG/FAIL: Flag the data set in the LIMS dashboard and send an alert to the scientist's ELN inbox with a suggested root cause (e.g., "Low signal-to-noise detected in column 3. Possible liquid handler tip clog.").

Step 3: Scientist-in-the-Loop Review

- The scientist reviews the flag and the AI-suggested annotation in the ELN.

- They can accept, modify, or reject the annotation. This feedback is logged and used to retrain and improve the AI's suggestion algorithm.

Step 4: Continuous Learning Loop

- All validation outcomes and scientist feedback are stored.

- Quarterly, the dataset is used to fine-tune the classification model, improving its accuracy and root-cause suggestion relevance.

The integration of AI with LIMS and ELN systems, as demonstrated in these protocols, creates a foundational infrastructure for the self-optimizing laboratory. It transforms these systems from passive repositories into active participants in the scientific method. This approach directly supports the core thesis that AI tools are most effective for automation when deeply embedded within the existing data lifecycle, enabling end-to-end workflow management that is predictive, adaptive, and continuously improving.

Overcoming Challenges: Troubleshooting and Optimizing Your AI-Enhanced Lab

Application Notes

Within the thesis on AI tools for automated laboratory workflows, three interconnected pitfalls critically hinder successful implementation: data quality, integration complexity, and skill gaps. These challenges are prevalent across genomics, high-throughput screening (HTS), and translational drug discovery.

1. Data Quality Pitfalls: AI models are fundamentally reliant on input data quality. In laboratory settings, common issues include:

- Inconsistent Annotation: Manual or legacy system data entries lead to non-standardized naming for compounds, cell lines, and targets.

- Batch Effects: Technical variation between experimental runs (e.g., different reagent lots, instrument calibrations) can introduce systematic noise that AI may misinterpret as biological signal.

- Missing Metadata: Incomplete experimental context (e.g., passage number, precise buffer conditions) reduces data reproducibility and model generalizability.

2. Integration Complexity: Deploying AI tools requires seamless data flow between heterogeneous systems, creating a "plumbing" challenge.

- API Sprawl: Laboratories utilize instruments from multiple vendors (e.g., PerkinElmer, Agilent, Tecan), each with proprietary data formats and communication protocols.

- Legacy System Incompatibility: Older Laboratory Information Management Systems (LIMS) and Electronic Lab Notebooks (ELN) often lack modern, machine-readable data export functionalities.

- Data Silos: Research data frequently remains isolated within specific departments (e.g., medicinal chemistry, in vitro biology, DMPK), preventing the creation of unified datasets necessary for holistic AI analysis.

3. Skill Gaps: The effective use of AI tools demands a hybrid skill set that is rare in traditional lab environments.

- Computational Literacy Gap: Bench scientists may lack training in data science fundamentals, limiting their ability to critically evaluate AI model outputs or perform basic data wrangling.

- Domain Knowledge Gap: Data scientists and software engineers often lack deep biological or chemical intuition, leading to models that are statistically sound but biologically irrelevant.

- DevOps Gap: The ongoing maintenance, versioning, and deployment of AI pipelines require skills in software engineering and IT infrastructure that are not typically found in wet-lab teams.

Table 1: Survey Data on AI Adoption Barriers in Life Sciences (2023-2024)

| Barrier Category | Percentage of Labs Reporting as "Significant" | Primary Impact Area |

|---|---|---|

| Poor Data Quality / Standardization | 67% | Model Accuracy & Reproducibility |

| Integration with Existing Lab Systems | 58% | Implementation Time & Cost |

| Lack of Skilled Personnel (AI/Data Science) | 52% | Tool Utilization & Model Development |